Services

Related Pages

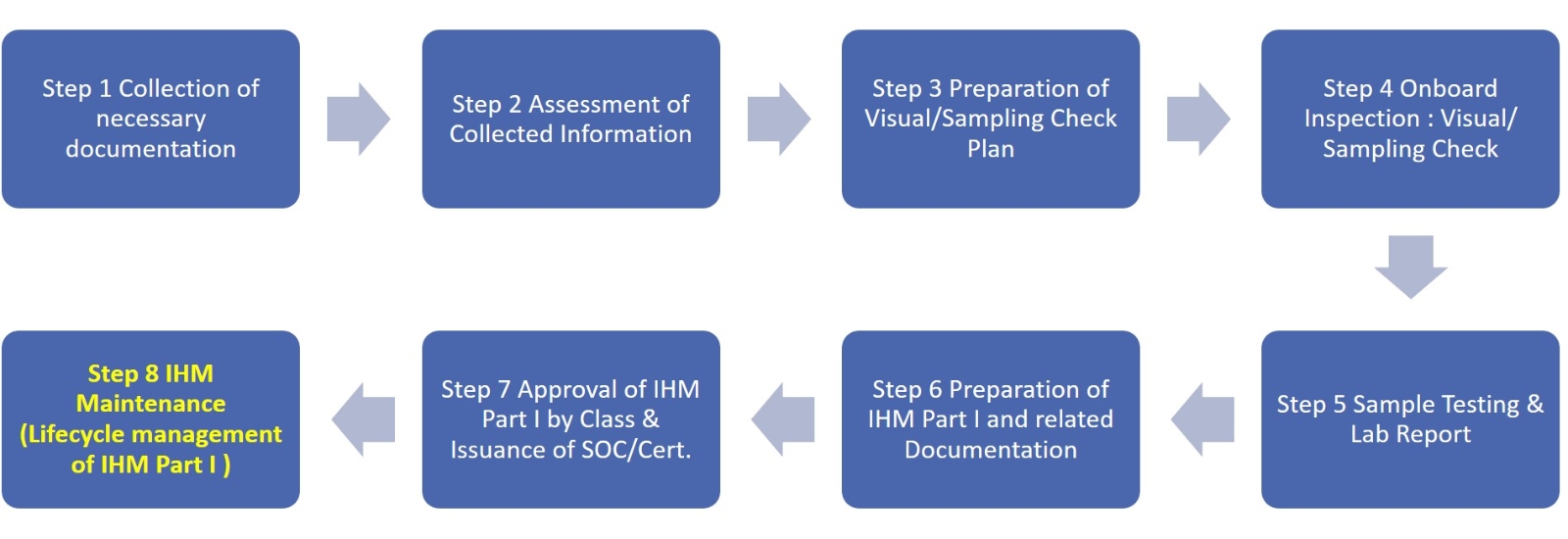

IHM Maintenance

Background to IHM Maintenance

Hazardous materials can impair our lives and the environment without proper management. They must be correctly identified, managed, and recycled over the entire span of the ship’s lifecycle. As part of these management processes, it is essential for ships to maintain and regularly update their Inventory of Hazardous Materials (IHM) as mandated to do so under the European Union Ship Recycling Regulations (EUSSR) and Hong Kong Convention (HKC) for vessels above 500 GT. IHM maintenance is vital for ships to reduce health risks to crew members as well as to ensure that mooring requirements are met.

While conducting an IHM survey and obtaining an approved report is the basis for compliance, it is important to remember that IHM is a living document, so it needs to be frequently updated throughout the entire lifespan of your vessel.

The IHM consists of three main parts:

- Part I: contains hazardous materials contained the within the ship’s structure or equipment, their location, and approximate quantities. It is this part which clarifies whether the ship complies with the regulations surrounding hazardous materials on board;

- Part II (prior to recycling): Operationally generated wastes; and

- Part III: Stores.

According to regulation (EU) 1257/2013 of the European Parliament and the Council on Ship Recycling (hereinafter referred to as “EUSRR”), Part I of the IHM should be properly maintained and updated throughout the operational life of a ship. It should reflect new installations containing any hazardous materials that has been referred to in Annex II of the regulation, and relevant changes in the structure and equipment of the ship. Therefore, shipowners should establish the necessary procedures on-board the ship and within their companies to fulfil their long-term environmental responsibilities.

Vessel Lifetime Quality Management

The IHM must be properly maintained and updated throughout the operational life of the ship, and it will supplement any Inventory Certificate or Statement of Compliance issued by a member state, third country, Regional Office (RO), or any authorized organization.

It is the responsibility of the ship owner to maintain Part I of the IHM over the lifetime of the ship. Part I of the IHM should belong to the ship, while both the continuity and conformity of the information it contains should be confirmed. This is especially important if the flag, owner, or operator of the ship changes.

Shipowners should designate a person responsible for maintaining and updating the inventory. This person should manage the IHM inventory in accordance with IMO guidelines. The duties of the designated person should be incorporated into the shipowner’s quality management system.

The lifetime quality management system should include specific provisions to safeguard the quality and continuity of the IHM during the building, buying or selling of a ship. In particular, this is useful when changing the ship’s registry or designated personnel. Futhermore, this guarantees a credible document is available for shipowners when the decision to recycle a ship is made.

The quality management system should highlight the procedures implemented to ensure the proper updating of the IHM during scheduled or unscheduled works. This might involve changes, replacements or repairs to the structure, equipment, systems, fittings, arrangements or materials, as this may have an impact upon the inventory.

Proper maintenance of an archive of all the associated documentations should also be included in the lifetime quality management system and should ensure that new installations of equipment, repairs, and refitting’s are accompanied by a Material Declaration (MD) and a Supplier Declration of Conformity (SDoC), which are to be provided by the suppliers of the parts and equipment delivered. As part of the lifetime quality management system, shipowners may include a random sampling policy for new or existing ships.

Finally, there assurances should be made that IHM development and maintenance shall be undertaken by competent entities (i.e., IHM experts) in accordance with recommended guidance (i.e., the EMSA’s best practice guidance document and the relevant IMO guidelines). A software tool may be used to support the IHM upkeeping process and the management of all relevant documents, information and data.

Why choose CTI Marine Services

We are delighted to be able to provide our clients with the following IHM Maintenance services:

- An experienced group of certified hazmat experts to perform IHM maintenance & provide training and/ or awareness support to suppliers

- Comprehensive assessment based on our extensive & continuously updated database regarding hazardous materials based on the IHM & hazmat surveys performed by CTI on over 3000 projects/vessels including plug lab testing of 100,000+ samples per year.

- A service accredited by all major classes in conducting IHM and hazmat surveys including DNVGL, LR, ABS, BV, KR, RINA and CCS.

- In-house lab testing support in situations where there is documentation (e.g. MD, SDoC) not available or if it is non-credible.

IHM Maintenance Model offered by CTI

Key Highlights of CTI IHM Maintenance Model

- Model is well supported by a group of experienced hazmat personnel

- Secure cloud platform for database management, which is under continuous improvement & development

- CTI can assist clients in identifying PO line items presumed to contain hazmat (Availability of detailed list of store/spare items confirmed to contain hazmat - sourced from CTI IHM survey projects for further guidance on HKC + EUSRR Indicative List)

- CTI will follow up with suppliers to collect the MD and SDoC and reminders will be sent regularly

- CTI can help confirm hazmat presence by referring to continuously updated in-house MD and SDoC database (If the documents are not provided by suppliers)

- CTI can provide in-house lab testing support if the MD or SDoC is unavailable

- As part of the maintenance contract, CTI offers 20 asbestos sampling tests each year per vessel free of charge

- Awareness training is offered as part of the MD and SDoC sourcing from suppliers

- CTI can provide detailed reporting for IHM maintenance activity so that the client can use it for flag/class/PSC inspection

- Quarterly Tracking Sheet to update Client on MD, SDoC status & PO line items confirmed to contain hazmat

- Annual IHM Maintenance Report to summarize the activity per vessel per year

- CTI can assist Client to build up the Purchasing Policy in line with HKC & EUSRR guidelines

- CTI will provide guidance & training support to Suppliers as required

Get in touch

If you have any questions or comments please don't hesitate to contact us

Services

Fuel Testing Solutions Water Compliance Services IHM & Recycling Asbestos Management Solutions NDT&UTMContact Us

192 Pandan Loop,

#05-27 Pantech Business Hub,

Singapore 128381

T +65 6271 8622