Services

Related Pages

Fuel System Check

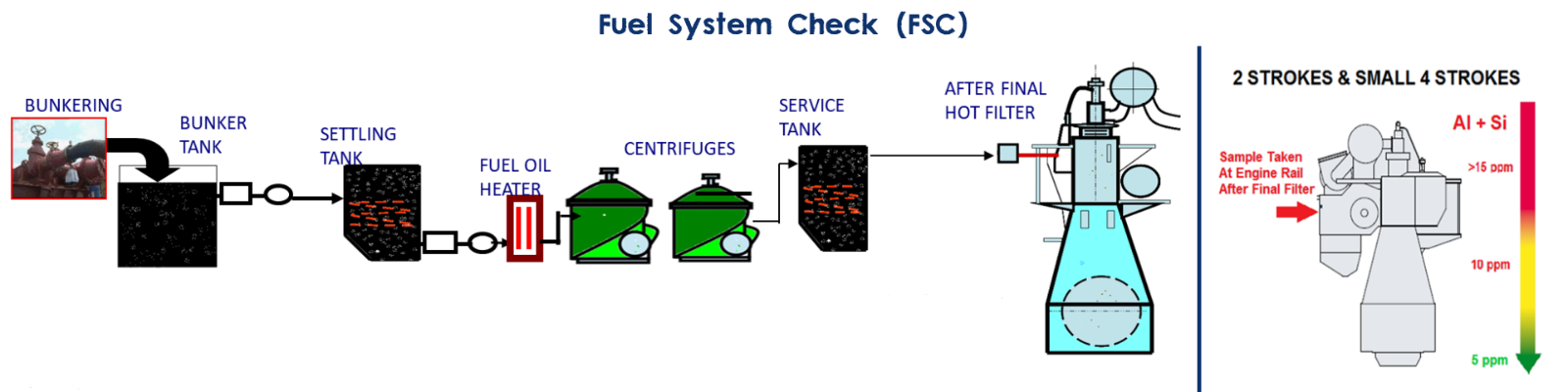

We recommend a comprehensive fuel system check is regularly carried out on-board ships to ensure that the build-up of Catalytic fines (‘cat fines’) does not occur. Preventing accumulations of cat fines is essential to ensure that the engine of the vessel does not become clogged with these particles, as they can cause damage to several engine components such as to the fuel pump, plungers, engine liner, piston rings and other mechanical components. Testing bunker fuel is critical to operating the ship effectively and efficiently, thereby reducing downtime and the potential for mechanical problems to occur.

ISO8217 was published in 2010 specifying the requirements for petroleum fuels for use in marine diesel engines and boilers, the cat fines limit for RME 180 fuels were reduced to 50 mg/kg and 60 mg/kg for RMG and RMK fuel grades respectively. Engine builders recommend that after onboard treatment, fuels entering the engine should have a cat fines concentration of less than 10-15 ppm.

Operators should be more concerned with the level of cat fines in the fuel entering the engine than the level of cat fines in the fuel from the bunkering sample, as accumulated cat fines in the fuel oil system is usually unknown without testing.

When the vessel receives fuels with a cat fines concentration of more than 30 ppm, a Fuel System Efficiency Check should be carried out to ensure that the separation efficiency is up to standard. This will help the engineers ascertain whether the fuel treatment systems on-board can reduce the cat fines content to a safe level.

Cat fines are hydrophilic, so these molecules or molecular entities are attracted to water molecules and thus tend to be dissolved by water. Therefore, regular draining of the service and settling tanks will reduce the volume of cat fines, which are drained with the water.

It is recommended that ship operators use 10-micron hot filters instead of 50-micron filters, which will also help to reduce the amount of cat fines reaching the engine.

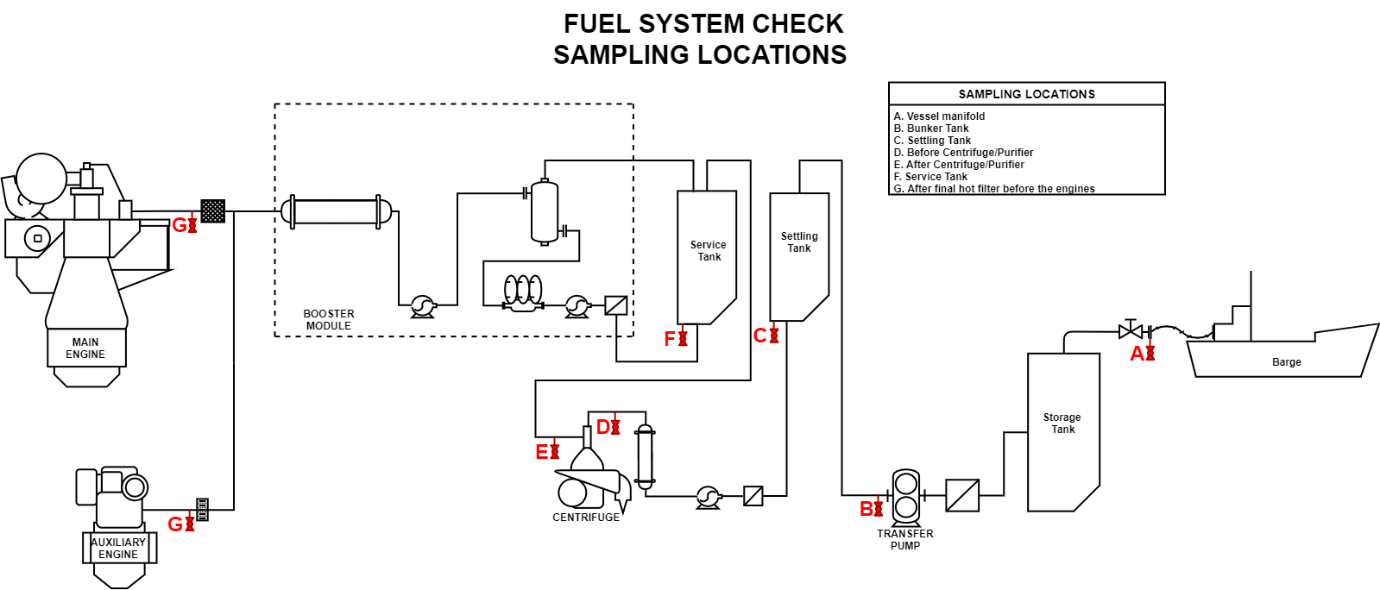

The vessel crew should check the fuel separation and treatment systems by periodically sending onboard samples to Maritec, which are to be obtained from the following locations, for testing:

A. Vessel manifold

B. Bunker Tank

C. Settling Tank

D. Before Centrifuge/Purifier

E. After Centrifuge/Purifier

F. Service Tank

G. After final hot filter before the engines

Limiting the catfines concentration entering the engine will increase the mean time between overhauls and improve the service life of engine components.

Get in touch

If you have any questions or comments please don't hesitate to contact us

Services

Fuel Testing Solutions Water Compliance Services IHM & Recycling Asbestos Management Solutions NDT&UTMContact Us

192 Pandan Loop,

#05-27 Pantech Business Hub,

Singapore 128381

T +65 6271 8622